Knife Blog

Archive

Search within Knife blog

Manufacturing process of Sakai knives

06/04/2016Sakai Knives

In a previous blog I wrote about the brief history of Sakai knives, but I would like to write about manufacturing process of Sakai knives today.

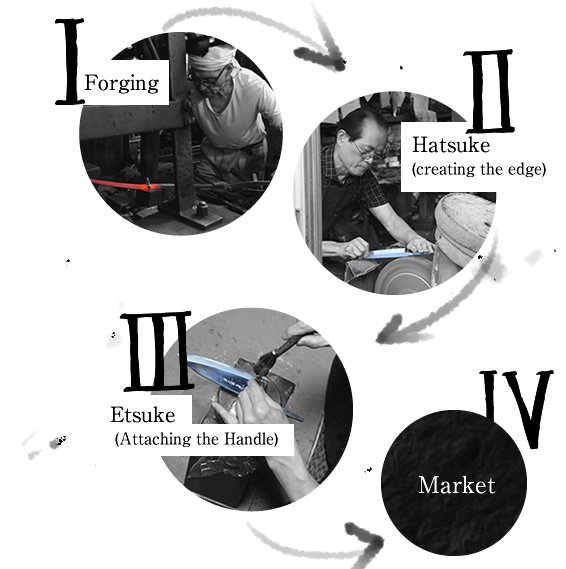

Manufacturing process of Sakai knives are divided into 3. One is forging by blacksmith, another is sharpening, and the other is attaching handles by wholesalers like us.

Blacksmith creates the base of knives from soft iron and steel. Beginning with Hagane-tsuke, which means forging soft iron and steel, manufacturing process includes Yaki-ire and Yaki-modoshi. Yaki-ire is cooling with water immediately after heating at 750 to 800 degrees. Yaki-ire enhances hardness of steel. Yaki-modoshi is heating at 160 to 180 degrees again after Yaki-ire. Yaki-modoshi creates viscosity and makes knives strong. I guess that there are around 30-40 blacksmiths in Sakai City.

Then, a Hatsuke craftsperson sharpens the base of knives. Most Sakai knives are single-edged. I guess there are around 30 Hatsuke craftsperson in Sakai City. I will write about the detailed process of Hatsuke in another blog.

Then, wholesalers like us attach handles, engrave logo, adjust distortion, box knives and sell them mainly to retailers. I guess the number of wholesalers in Sakai City is around 30.